Forums » News and Announcements

Annual Aviation Borescope Review

-

Annual Aviation Borescope Review

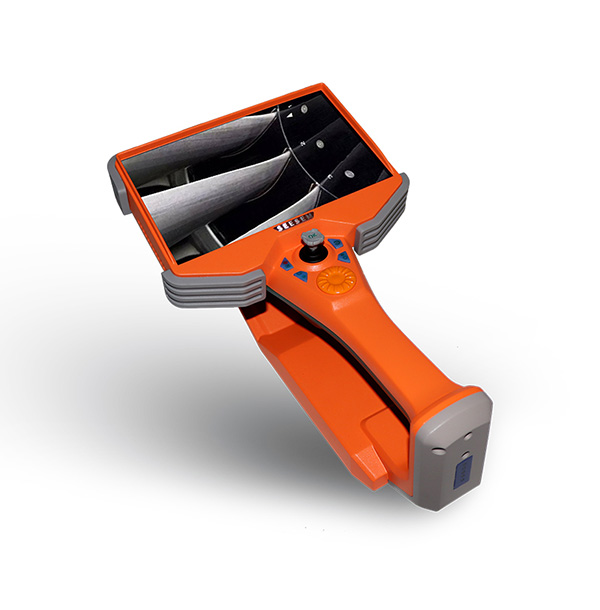

What is the purpose of your Remote Visual Inspection, and what are you inspecting? With today’s RVI being accomplished with borescopes, there is a wide variety of these fantastic pieces of equipment to choose from, but it hasn’t always been this way.To get more news about video borescope, you can visit seesemborescopes.com official website.

A Little History

The first recorded instance of a remote optical viewing apparatus is dated to 1921, where an eye doctor was asked to develop a device to peer inside an industrial turbine rotor.

Later, during world War II, the members of the military had developed crude visual inspection devices to inspect the barrels of their weapons. This is where the term ‘borescope’ is said to have been born.It wasn’t until 1960 that the first commercially produced borescope became a reality. It was a rigid tube, with the required optics, to peek straight away inside cavities that were beyond the limits of the human eye to directly observe.

In the mid-1800’s, scientists and inventors had discovered that light could be bent by traveling through streams of water. This was the very beginnings of what is known as fiberoptics.Fiberoptics allows the internal refraction of light through flexible fibers, usually silica or plastic. This technology is used everywhere today. In the mid-1960’s, fiberoptics was used for the first time in conjunction with borescope optics to produce the first ‘fiberscope’. This allowed inspection not only directly in line with the entry axis, but sideways and around corners.

Now, 60 years later, less than an average lifespan, there is a myriad of choices that will best suit the inspection needs of every type of aircraft and engine.

Today’s Remote Visual Inspection Equipment Choices

The current capabilities of the borescope have advanced through several stages, with each adding a new functionality.The very first borescope provided just a ‘look-and-remember’ method. It was similar to a microscope, only with the target much further away.

Benefits to the Aviation Industry

The greatest realized benefit is a near incalculable savings on inspection because disassembly to access inspection points has become either non-existent or is greatly reduced.Also, scopes used for inspection that utilize picture/video/audio capture particularly useful and important maintenance record entries.

With wi-fi enabled scopes, other technicians can be watching the ongoing inspection, right alongside the operator performing the work. Who doesn’t want a second set of eyes?

Scopes For Piston Engines

An internal inspection of the cylinder and the valves can help assess the cause of a low compression check. In the pre-scope days, if a cylinder was below limits and could not be corrected in some fashion, the jug was usually pulled to determine the flaw. There might have only been a piece of build-up on the exhaust valve that could have corrected itself on the next engine run.An article published in the May 2017 edition of AOPA Pilot discusses Continental Motors’ 2003 Service Bulletin SB03-3, directing that cylinders with low compression test results be inspected with a scope. This was to determine if the cause was temporary as mentioned, or potentially catastrophic.

They required that if the visual inspection showed nothing major, the aircraft had to be flown for at least 45 minutes, then the compression test done a second time. If it failed again, then the cylinder needed pulled.